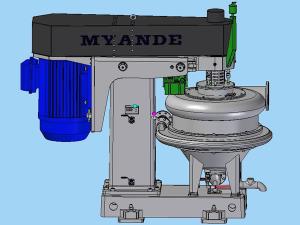

Centrifugal Separator

Myande's MH model centrifugal separator is widely used in starch processing for starch milk pre-concentration, starch milk washing and concentration, and protein dewatering and concentration.

Features

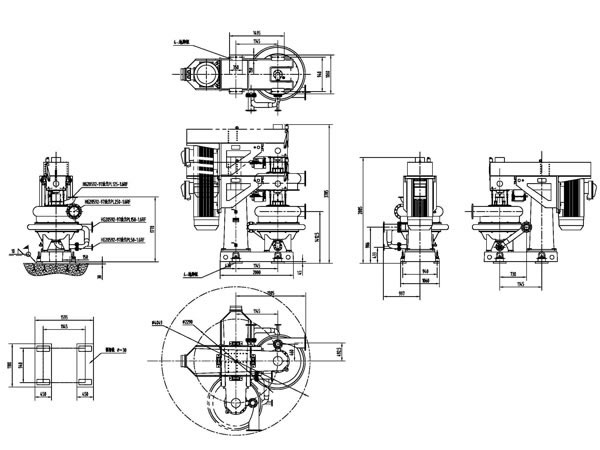

1. This starch processing separator has a unique hanging driving mechanism that eliminates the axle load on the shaft and bearings, increasing the separator's service life.

2. Maximal disc and rotating drum sizes for increased capacity and separation efficiency.

3. Large nozzles with a cam-lock device minimize blockage for long-term continuous separation.

4. High precision dynamic balancing ensures the centrifuge rotates and runs smoothly.

5. Temperature sensors on each bearing and vibration sensors on the main shaft assembly provide real-time monitoring.

Parameters

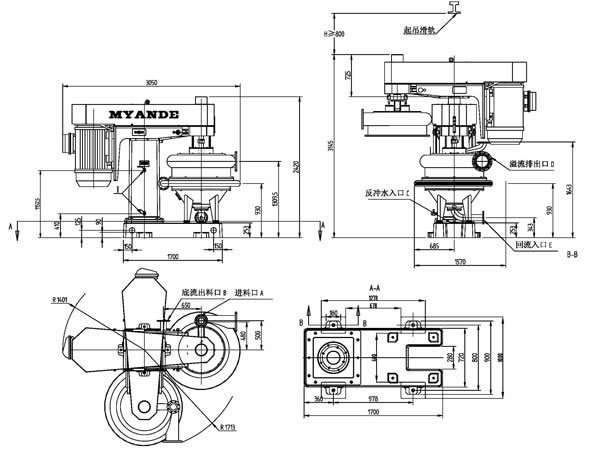

| Model | ||

| Max Capacity (m3/h) | 22 ~ 115 | 45 ~ 225 |

| Shaft Rotation Speed (RPM) | 3300(Max) | 2900(Max) |

| Nozzle Quantity | 20 | 30 |

| Inner Diameter Rotating Drum (mm) | 780 | 940 |

| Power (Kw ) | 110/132 | 220/250 |

| Dimensions (length x width x height) (mm) | 3050×1570×2420 | 3400×1780×2850 |

| Notes | MH30-PS (main separator) | MH36-PS (main separator) |

| MH30-GT (gluten thickener) | MH36-GT (gluten thickener ) | |

| MH30-MST (pre-thickener ) | MH36-MST (pre-thickener) |

Русский

Русский Español

Español