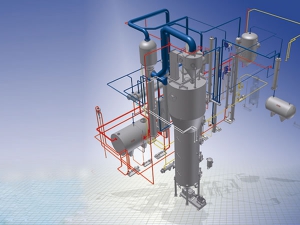

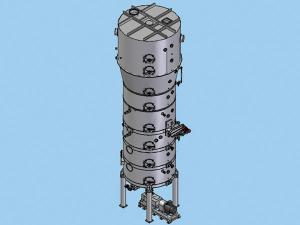

DTDC (Desolventizer, Toaster, Dryer, Cooler)

Myande’s DTDC is an innovative desolventizer toaster dryer cooler designed based on customer's production requirements for oil processing plants. This oilseed equipment has a unique structure for desolventizing, roasting, drying, and cooling. Full automatic control not only reduces steam consumption but also makes operation simple and reliable for a superior finished product.

Product Functions and Features

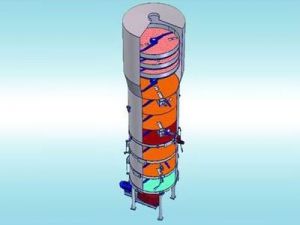

Function: To remove solvent from spent meal, and then toast, dry and cool meal.

Features

1. High energy efficiency: Perforated layers ensures material is thoroughly steamed.

2. Complete desolventization: Low residual solvent content in meal and adjustable moisture contentensures low solvent consumption and safe use of meal.

3. High quality meal: Minimal protein denaturalization and meal with improved nutritional value, color, flavor and particle size.

4. Excellent sealing effect: Prevents material or solvents from leaking out of the desolventizer machine.

5. Versatility: Integrates desolventizing, toasting, drying and cooling.

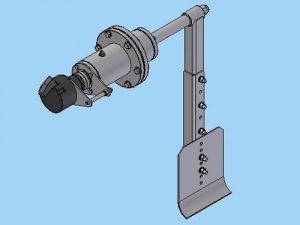

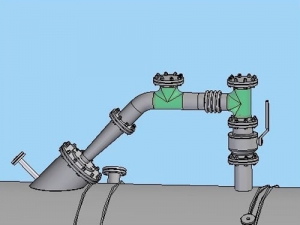

6. Steam jet device in the flash layer and direct steam layer for balanced pressure and better recovery of steam and solvent

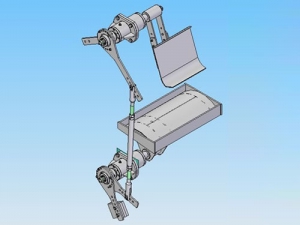

7. Features advanced automatic level control, import sensors, easy installation, durable and reliable operation, wear-resistance, and adjustable layer height.

8. Automatic door structure and adjustable height, weight, and opening size, great sealing.

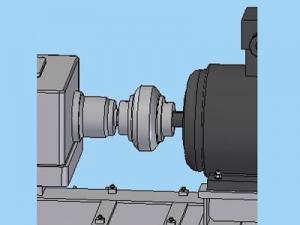

9. Special import coupling that is temperature resistant and operates in all working conditions.

10. We can install different layers according to different production needs. DTDC can be divided into two separate devices DT and DC to meet the needs of large scale production which will desolventize meal completely and keep the scent and granule size of the meal intact.

Parameters

| Name | Specification ( diameter/cm ) |

||||||

| DTDC | 200 | 220 | 250 | 280 | 300 | 320 | 340 |

| 360 | 380 | 400 | 420 | 450 | 500 | 550 | |

| 600 | 660 | ||||||

| Note 1 : Number of layers are determined by customer need. |

|||||||

| Note 2 : Refer to the sheet for basic parameters, but we can also customize coolers. |

|||||||

Русский

Русский Español

Español