1. 700MTPD Sunflower, Canola,and Soybean Cake Extraction Turnkey Project in Ukraine

Wanting to increase their capacity and production efficiency, one of the leading producers of edible oils in Ukraine entrusted Myande to build a new 700MTP sunflower, canola, and soybean cake extraction line in 2011.

This extraction line consists of a bucket type extractor, DTDC, drag conveyors, evaporator, condenser, stripper, absorber, desorber, cyclone, and pumps. Installation for this oilseed extraction project started in late 2012 and was completed in 2013. Myande also supplied materials in preparation for their plant as well as their civil engineering design, automatic control system, and supervision for the installation.

Since then, this automatic extraction line has proved to have high rates of productivity and yield high quality products, significantly increasing this customer’s brand value in the oil and fats industry in Ukraine.

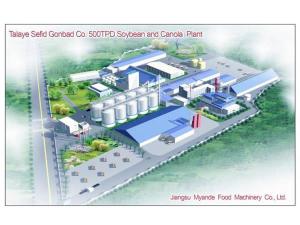

2. 500MTPD Canola & Soybean Preparation (with Pre-Pressing & DeHulling) and Extraction Plant Turnkey Project in the Middle East

In 2010, Myande supplied a 500MTP canola and soybean preparation (including pre-pressing & dehulling) and extraction plant to one of the leading producers of canola oil and soybean oil in the Middle East. This plant consists of a canola pressing section, soybean cracking & dehulling section, and extraction section. The preparation line includes a vibration screener, weighing machine, conditioner, cracker, aspirator, flaker, cooker, expander, dryer and cooler. The extraction line includes a bucket extractor, DTDC, drag conveyor, evaporator, condenser, stripper, absorber, desorber, cyclone, and pumps. In addition, Myande provided the civil engineering design, automatic control system, and supervision for the installation.

Since then, this preparation with pre-pressing and extraction line has proved to have high rates of productivity and yield high quality products, significantly increasing this customer’s brand value in the edible oil industry in the Middle East.

3. 1500MTPD Soybean Preparation with Dehulling & Expander Turnkey Project in India

In 2012 Myande supplied a 1500MTP soybean preparation line that includes dehulling and expander equipment to IB Group in India. Installation started in 2012 and was completed in 2013. The preparation line includes a vibration screener, weighing machine, conditioner, cracker, aspirator, flaker, expander, dryer and cooler. In addition, Myande provided the civil engineering design, automatic control system, and supervision for installation.

Since then, this oil seeds preparation line has proved to have high rates of productivity and yield high quality products, significantly increasing IB Group’s expansion as a leading soybean oil processer in India.

4. 1000MTPD Palm Kernel Cake Extraction Turnkey Project in Indonesia

In 2011, Myande supplied a 1000MTP palm kernel cake extraction plant to MM Group, a leading manufacturer and supplier of palm oil in Indonesia. This extraction line consists of a bucket extractor, DTDC, drag conveyor, evaporator, condenser, stripper, absorber, desorber, cyclone, and pumps. In addition, Myande provided the civil engineering design, automatic control system, and supervision for installation.

Since then, this extraction line has proved to have high rates of productivity and yield high quality oil and meal with low energy consumption.

|

Extractor of 1,000MTPD Palm Kernel Solvent Extraction Plant |

Solvent Spray and Miscella Recycle Piping of Extractor |

||

|

Miscella Evaporation and Solvent Recovery |

DTDC & Piping System |

||

5. 1000MTPD Soybean Preparation and Extraction Plant Turnkey Project in Vietnam

In 2011 Myande supplied a 1000MTP soybean preparation and extraction plant to the Oil & Fats Company, a leading processer and supplier of soybean oil and meal in Vietnam. This soybean preparation and extraction plant consists of a soybean cracking & dehulling section, flaking section and extraction section. The preparation line includes a vibration screener, weighing machine, conditioner, cracker, aspirator, flaker, expander, dryer and cooler. The extraction line includes a bucket extractor, DTDC, drag conveyor, evaporator, condenser, stripper, absorber, desorber, cyclone, and pumps. In addition, Myande provided the civil engineering design, automatic control system, and supervision for installation.

Since then, this soybean preparation and extraction plant has proved to have high rates of productivity and yield high quality products, allowing the company to rapidly recover their initial investment and increase their profits.

Русский

Русский Español

Español